“The biggest part of our digital transformation is changing the way we think.”- Simeon Preston, CEO, Bupa.

In today’s world, digital transformation is not a choice for businesses anymore. Yes, it has become a necessity due to its limitless opportunities to help them grow.

![]()

By implementing the digital transformation in manufacturing, companies can easily enhance their productivity and efficiency.

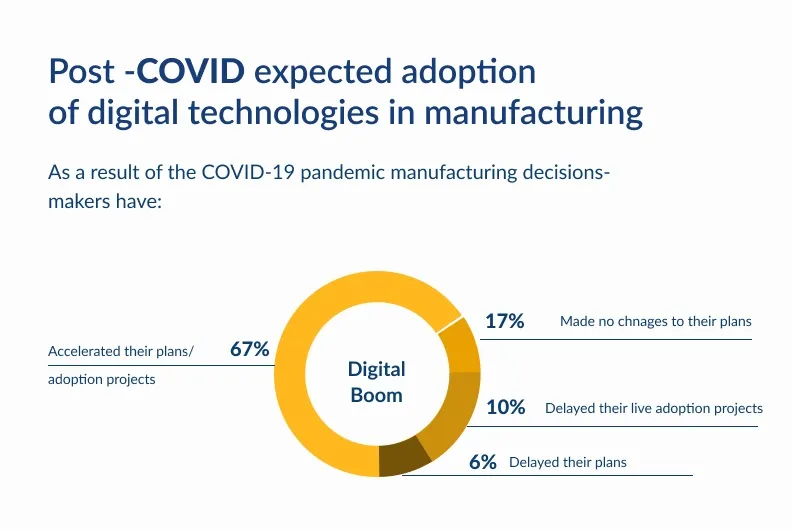

Did you know that 67% of manufacturers have accelerated digital projects because of COVID-19?

Manufacturing companies have realized that they need to innovate their business to keep up with the changes taking place at the global level. Being in the industry, if you also want to know more about it, then this blog is for you.

Today, I will reveal the top advantages of digital transformation in manufacturing and its upcoming trends. However, let me first take you through some of the manufacturers’ current challenges.

Table of Contents

Current Challenges Among Manufacturers that Digital Transformation Can Tackle

![]()

The challenges making a digital transformation company core necessity for today are many, and I have mentioned the key ones here:

1. Product Delivery Challenges

- Many transaction points often result in stockouts and high order turnover rates.

- Short product lifecycles lead to discontinuation or obsolescence issues.

- Late shipments with little or no information on the cause of delay, making it difficult for customers to plan their business operations accordingly.

Ready to overcome challenges and drive success?

2. Cost of Quality Challenge

- Customers may complain of defective products, resulting in excess costs that manufacturers will need to incur.

- Short product lifecycles can cause supply chain problems. For instance, it is difficult for suppliers to produce parts on time if there is any uninformed change at an initial stage.

- It is challenging for manufacturers to track defects.

- Defects may be considered one-time problems instead of being tracked, leading to false projections. This can result in incorrect pricing and incorrect inventory management practices.

3. Organizational Capability Challenges

- High variability in productivity due to lack of demand visibility.

- Fewer interactions among business units and suppliers lead to higher operating costs.

- It is challenging to conduct continuous improvement activities because of managerial focus.

4. Operational Challenges

- COVID-19 has also revealed the significance of digital technologies in the manufacturing industry.

- Throughout the pandemic, manufacturers like you encountered operational difficulties that encouraged the flaws in their current businesses.

- Real-time data regarding the supply chain could allow manufacturers to respond quickly to supply deficiencies.

Check out the image from the Manufacturer’s study and IBM showing the techniques manufacturers concentrated on during COVID-19 and could profit from digital technologies.

![]()

5. Productivity Challenge

- Traditional management approaches are no longer effective in improving profitability.

- Operational excellence is more significant pressure, resulting in new tools and technologies.

- High variability due to lack of demand visibility results in lower productivity rates. This also makes it difficult for organizations to adjust their capacity and workforce.

6. Innovation Challenge

- Traditional management approaches are no longer effective in improving profitability.

- There is more significant pressure for operational excellence, resulting in developing new tools and technologies to improve quality, efficiency, and competitiveness.

- High variability due to lack of demand visibility results in lower productivity rates. This also makes it difficult for organizations to adjust their capacity and workforce.

Digital Transformation Benefits in Manufacturing

“We have seen more Digital transformation in 2 months than in the last 2 years” Satya Nadella, CEO, Microsoft.

![]()

By implementing digital transformation in manufacturing, companies can improve their operational efficiency by increasing productivity and optimizing costs. Some of the main benefits of adopting a digital platform for your manufacturing business are as follows:

1. Increased Productivity – Who Doesn’t Want that?

By adopting digital tools for Manufacturing, companies can easily enhance their effectiveness and increase the number of products manufactured per year. It also leads to reduced costs per product due to automation. Also, it helps in reducing non-productive time (NPT), which leads to improvement in profit.

2. Improved Customer Experience As Customer is King!

By implementing digital transformation, companies can easily cater to their customers’ needs and give them the best possible experience. With the presence of new technologies like social media, analytics, IoT, etc., they can keep themselves updated about their target market’s requirements and offer them what they want. It also helps in improving relationships with their customers.

3. Better Workforce Management to Avoid Any Hassle and Delays!

Digital transformation in Manufacturing companies helps optimize human resources and boost overall productivity by automating business processes. It aids in reducing a significant amount of the workload, increasing the number of products manufactured, and optimizing labor costs. By implementing digital tools, companies can have better control over their workforces.

4. Competitive Edge – Don’t You Want to be at the Top?

By implementing digital transformation, companies can gain a competitive edge by using modern tools like IoT, analytics, social media, etc., to understand their target customer better and offer them improved products that they want. By optimizing business processes with digitization, companies can gain the upper hand over their competitors.

5. Improved Decision Making, Which is Really a Big Concern

Digital transformation helps businesses make informed and accurate decisions to visualize and analyze product data to improve quality, performance, and productivity. It also offers companies a better picture of the market by providing better insights into customer behavior and purchasing power. Also, it helps in getting accurate and real-time information about the cost and time involved in various processes.

6. Improved Inventory Management – No Manual Checks Any More!

Digital transformation helps companies stay updated by integrating their inventory management systems with modern tools like IoT, social media, analytics, etc.

Companies can avoid performing manual checks or wasting time finding the data by implementing digitization. It helps them keep track of the inventory and remain updated about products’ location, quantity, quality, etc.

7. Reduced Costs that Every Business Looks Forward to

Companies can reduce cost per product by increasing productivity and efficiency via digitization. They can manage their expenses more effectively by using advanced tools like analytics, machine learning, etc., to optimize processes and infrastructure. Also, they can reduce waste by finding out various activities that are non-value adding or time-consuming.

8. Improved Inventory Visibility -Transparency is the Key to Success!

Companies can improve their equipment management by integrating different technologies like IoT, social media, etc., through digital transformation. It also helps them trace each piece of equipment and provides accurate data about the location, usage, market value, etc., of equipment. This, in turn, helps them manage their inventory better and reduces the theft of expensive equipment.

9. Better Strategies that Lead to Higher Growth!

Companies can implement better strategies by using innovative technologies like machine learning to develop analytical reports and respond to customer demands faster than ever before. It helps companies stay ahead of the curve and understand their customers better, improving their reputation.

![]()

Boost productivity, customer satisfaction, and competitiveness.

Top Digital Transformation Trends in Manufacturing 2022

1. Autonomous Systems

1. Autonomous Systems

Autonomous systems leverage information about the surrounding atmosphere from sensors. It includes cameras, light & audio sensors, infrared, radar, ultrasound, and more to explore real-time situations, adapt, and react without human intervention. Some autonomous systems in manufacturing include:

- Autonomous robots

- Drones

- Autonomous warehouse and factory systems

2. IIoT

![]()

Industrial Internet of Things (IIoT) services is a sub-category of IoT that concentrates on apps in industrial domains. IIoT is revolutionizing the manufacturing sector by allowing businesses to regulate the production process instantly. It even helps them to make more data-driven conclusions with manufacturing analytics. As per McKinsey prediction, IIoT will be a $500B market by 2025. Advantages of IIoT technologies include:

- Predictive maintenance

- The energy efficiency of individual machines

- Demand forecasting

- Supply chain visibility

3. Robotics

![]()

Robotics is an approach to manufacturing that applies machines, tools, computer control systems, and software. It is possible to use Robotics in various manufacturing processes, including flexible automation for consumer goods, semiconductors, telecommunication equipment, pharmaceuticals, etc. Some examples of robotics in production include:

- Machine-made furniture

- Ironing robots

- Autonomous maintenance robots

- Industrial robots

4. Cloud Robotics

It leverages the power of cloud computing to store, process, share and analyze data generated by smart devices or machines that include sensors, microcontrollers, networked systems, etc.

Also, cloud robotics allows corporations to remotely monitor their production process using real-time data, perform predictive maintenance and make informed decisions to improve efficiency. The key to implementing cloud robotics is to exploit the seamless interoperability of cloud technology and robotic technologies.

Some examples of cloud robotics applications in manufacturing include:

- Remote surveillance of machines and processes

- M2M communication between robots, smart devices, and other connected equipment

- Predictive maintenance

5. 3D Printing

Additive manufacturing is a form of 3D printing that adds material layer-by-layer to create a customizable product for specific applications. 3D printing is suitable for prototyping and direct investment casting.

However, it has limitations in terms of accuracy and surface finish. To overcome these restrictions, you can 3D print materials like metals and ceramics.

With 3D printing, you can even produce surgical implants based on CT scans of specific individuals, while some companies even use 3D printing to manufacture entire buildings.

6. Digital Twins

It is a virtual representation of a physical object or system, which you can use to monitor the performance of the object in real-time, predict potential problems and improve efficiency.

The technology behind digital twins uses data generated by sensors attached to physical assets, which are then transferred to the cloud for storage, analysis, and visualization. Some examples of digital twins in manufacturing include:

- Industrial process and equipment monitoring

- Lubricant usage tracking for optimum performance

- Plant equipment condition assessment

7. Industry 4.0

![]()

Industry 4.0 is a word coined by the German government to represent an evolution in manufacturing that will enable smart factories to use digital technologies like cloud robotics, IIoT, and Big Data. It promises to establish communications among intelligent objects (IoT) capable of:

- Sensing their location relative to other objects/equipment

- Collecting and analyzing data to optimize performance

- Transferring real-time data to SCADA, MES, and ERP systems for effective control over the production process.

Some benefits of Industry 4.0 include:

- Improved predictive maintenance

- Virtual commissioning, training & servicing of products

- Optimized production planning and supply chain management

8. Augmented Reality

AR or augmented reality is a type of user interface technology that superimposes computer-generated enhancements on the real world, allowing for contextual information to be displayed in sync with a person’s natural line of sight, thereby creating a more immersive experience. Some examples of AR technologies in manufacturing include:

- User manuals and training videos integrated with assembly instructions on product workbenches

- Virtual equipment or machine calibration/servicing

- Inspection & quality control with video overlay on physical functions

9. Robotic Process Automation (RPA)

A form of software automation, RPA is a business process management system. It allows employees to configure computer software or a “robot” to capture and analyze existing apps to automate business processes.

RPA robots are capable of understanding natural language, interpreting relevant data, initiating transactions, retrieving information from external sources, communicating with other digital systems, and interfacing with both humans via chatbots and non-technical users through the form of GUIs.

RPA is used in many processes related to manufacturing, e.g.:

- Tasks with low human intervention requirements

- Functions with high transaction volume

- Operations in physically distributed environments

- Applicable in cases where there is a need for processing large volumes of data and an inability to use advanced analytics

Discover transformative trends for enhanced efficiency and unlock your manufacturing potential!

10. Data Analytics and Machine Learning

Machine learning is an app of AI focusing on developing computer programs that can teach themselves to evolve as they acquire new data. Data analytics refers to strategies and tools for examining, organizing, analyzing, and interpreting several data sets to discover patterns and identify trends within the data.

Some examples of machine learning algorithms used in manufacturing include:

- Regression Analysis

- Decision trees

- Clustering analysis

- Recommender systems or predictive analytics

- Process optimization with process mining techniques

- Time-series forecasting and anomaly detection

Final Thoughts

Manufacturing has become an increasingly capital-intensive facility as it takes much more money to buy equipment and employ people to produce goods. Indeed, companies are discovering ways to cut costs while increasing production.

Some of the technologies discussed above promise to address these challenges by reducing waste, optimizing processes, ensuring quality control, and increasing productivity.

However, you cannot deploy such drastic changes in your business just like that. There is a need for expertise, and a digital transformation consulting company can help you. If you still have queries, mention them in the comment section below. All the best! I hope you have found this blog useful.